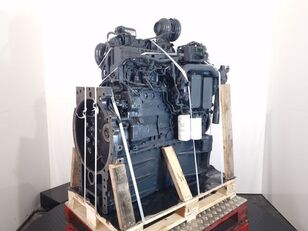

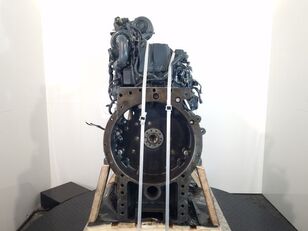

Moteur MTU FNER gas 20V4000L64 pour MTU 20V4000GS gas genset

Si vous décidez d'acheter un véhicule ou du matériel à bas prix, assurez-vous que vous communiquez avec un vendeur réel. Cherchez autant d'informations sur le propriétaire que possible. Un escroc peut se faire passer pour une société réelle. En cas de doute, contactez-nous en utilisant le formulaire de commentaires afin que nous effectuions un contrôle supplémentaire.

Avant d'effectuer un achat, étudiez attentivement plusieurs offres de vente afin de connaître le coût moyen du modèle de véhicule ou d'équipement que vous avez choisi. Si le prix de l'offre qui vous intéresse est très inférieur aux offres similaires, réfléchissez bien. Une différence de prix considérable peut indiquer la présence de défauts cachés ou une tentative d'escroquerie.

N'achetez pas de produits dont le prix est trop différent du prix moyen de produits similaires.

Ne consentez pas à payer une caution ou une avance douteuse. En cas de doute, n’hésitez pas à demander des précisions, des photos et des documents supplémentaires, vérifier l'authenticité des documents ou encore poser des questions.

C'est l'arnaque la plus répandue. Des vendeurs malhonnêtes peuvent demander une avance sur le montant total pour « réserver » votre achat. De cette manière, ils peuvent recueillir un montant considérable, puis disparaître.

- Faire un prépaiement sur la carte

- N'effectuez pas de prépaiement sans établir de documents confirmant le transfert d'argent si le vendeur vous semble suspect au cours de vos échanges.

- Transfert de l'argent sur le compte séquestre

- Méfiez-vous de ce genre de demandes, il est très probable que vous soyez en train de communiquer avec un fraudeur.

- Virement sur le compte d'une société avec un nom similaire

- Soyez vigilant(e), des fraudeurs peuvent se faire passer pour des entreprises connues en introduisant des modifications mineures dans le nom. Ne transférez pas d'argent en cas de doute sur le nom de l'entreprise.

- Substitution de ses propres coordonnées dans la facture d'une entreprise réelle

- Avant d'effectuer le virement, vérifiez que les coordonnées indiquées sont exactes et qu'elles appartiennent à l'entreprise indiquée.

Coordonnées du vendeur

Autriche

Autriche

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)

❖ Lloyd's CSC-certified (Convention Safety Container) for

trouble-free conventional transport (Rail, Road, Sea)

and stackable storage of the modules

❖ Plug & Play solution for the ease of “On site”

installation and operation

❖ Versatile use of the gensets (different operating

conditions)

❖ Weather-proof

❖ Minimum external dimensions, ISO 40’HQ container

❖ Proven tested design (Extensive testing before launch

as standard products)

❖ Combinable optional packages to suit various

demands

❖ Environment friendly provision (e.g. low noise level,

container floor sealed against leaking oil and water,

optional catalytic converter and CHP unit)

MTU Interface Panel (MIP):

Mounted directly on the base frame of all MTU

systems, the MTU Interface Panel (MIP) manages

engine and generator operation. It also controls

paralleling and synchronizing with other sources

of electricity, such as the utility or other generator

sets, and provides remote access and software

interfacing capabilities.

• Genset Control PLC

• Interface to Engine Control Unit ECU

• Interface to Alternator

• Bus interface to external (Modbus)

• On-base components cabled to MIP

MTU Module Control (MMC):

MTU’s highly customizable solution—the MTU

Module Control (MMC)—seamlessly links with

the MIP engine and generator set controls by

cable, making all vital data and functions

accessible to the operator from one convenient

location.

• Operator interface

• DC power supply

• Data Logging capability

• Remote connection to MTU available

• Control of off base components

The MIP/MMC consolidates the following controls and functions:

Generator Set Controls

• Starter Battery Charger

• Gas train control

• Engine oil system (refilling)

• I/O’s (Inputs/Outputs), auxiliary

drives

• Parallel/Island operation

• Load sharing

• PLC (Programmable Logic

Controller)

• AVR (Automatic Voltage

Regulator)

• Energy-Measure-Module –

controls

Engine Control Unit (ECU)

• Gas supply (mixture/lambda)

• Throttle / speed control

• Ignition control

• Turbo bypass

• Knocking detection / control

• Engine sensors / monitoring

• Emission sensor (NOx)

• Start / stop procedure

Accessory Controls

• Alarm system

• Data logging

• Visualization (webserver)

• MMC/MCS interfaces

(Ethernet)

• Customer interfaces (ex.

Modbus)

• HMI touchscreen

• Remote monitoring and

diagnostic

Condition: Brand New still in factory packaging

Model: 20V4000L64FNER

Volts: 11kV (11000 V)

Power rating: 2535 kWel

Frequency: 50hz

Speed: 1500 RPM

Engine:

Engine Model 20V4000L64FNER

Version 93800052350-V04-en-GB

Number of cylinders /

configuration 20V

Engine speed 1500 r/min

Bore 170 mm

Stroke 210 mm

Displacement 95.3 L

Lube oil Capacity 350 L

Exhaust gas emissions

NOx, stated as NO2

(dry, 5% O2)

< 250 mg/m³ i.N

CO (dry, 5 % O2) < 1000 mg/m³ i.N

Open skid mounting.

containerised solution available as well:

MTU 20V4000L64 powered by

❖ MTU gas genset of electrical power 2535kWe, 11kV,

50Hz , Pf=1, powered by MTU engine 20V4000L64

❖ ISO 40' High Cube Container

❖ Re-cooling system for engine and mixture cooling

circuit (without heat recovery)

❖ Generator output field including customer ‘s

connection

❖ MMC (MTU Module Control) for system control,

regulating ,diagnosis and protection

Features of Container version:

❖ Full transportability of the system (Rail, Road, Sea)